Rolla Transformer Enclosures

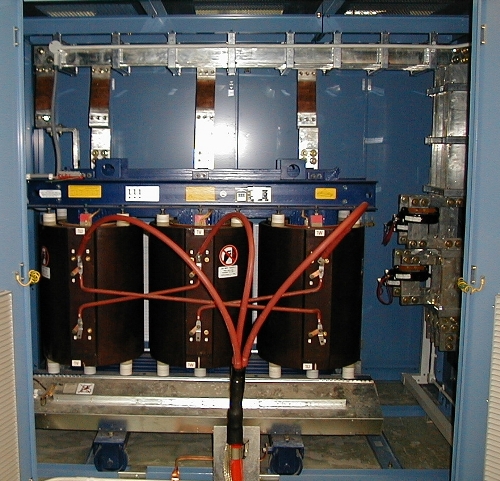

Rolla have been supplying transformer enclosures for many years, mostly as part of a package sub-station, but also some stand alone versions. Typically each enclosure will house a cast resin transformer with 11kV primary and 400V secondary, in ratings from 500kVA to 3.5MVA.

Each enclosure is test assembled in our works before it is painted.

Enclosures have an open floor, and assume that the transformer will sit on a solid base. We provide floor channels to spread the transformer load, and provide a guide to location.

They come in all shapes and sizes to suit the particular transformer and the associated switchboard. We also supply a complete busbar system to fit in the top of each enclosure, with bars arranged to connect directly to the adjacent incomer section.

The overhead busbars use our own type tested arrangement (Rolla KATTA® system).

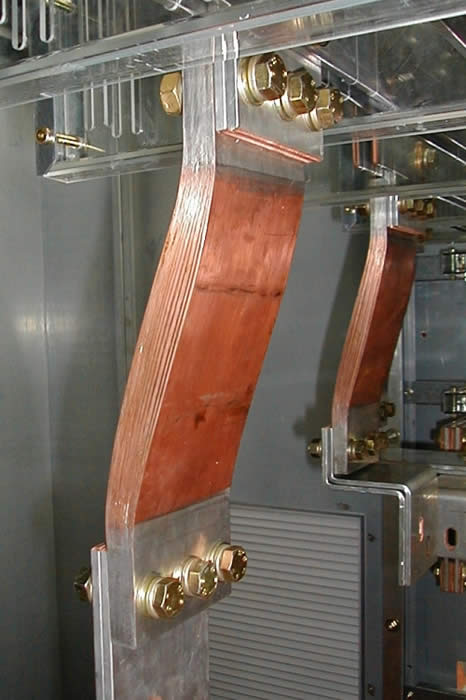

Connections on the LV side are through flexible links to provide adjustment and reduce vibration.

We also provide channels for the floor, to spread the load of the wheels (transformers usually weigh several tonnes).

As all the busbars are pre-manufactured, site assembly is usually quick and easy.

HV cables can come from above or below.

We can punch for an HV flange, to fit an external HV cable box if required.

The kit of parts is supplied on a pallet, with separate boxes for the copper busbars and loose fixings, bolts etc., ready for site assembly. In most cases the enclosure and the transformer are fitted on site at the same time, by the electrical contractor, who will also connect all the site wiring and carry out testing and commissioning.

Hinged doors provide access for maintenance, tap changing etc. Colour will usually be to match the switchboard to customer's requirements.

A key part of the design of these enclosures is the ventilation - air must be allowed in and out in order to keep the transformer cool. We use the transformer manufacturers data for the watts losses, whether AN or AF rated, and always allow spare capacity.

Most enclosures use simple coarse mesh (IP2X), as this has the best air transfer performance, but some sites use special non-vision transfer grilles.

Grille sizes calculated to suit ventilation requirements.

Removable enclosure sections, including the base, allow the transformer to be withdrawn and replaced, without complete disassembly. This will depend on the site access requirements, floor loading etc.

The air can enter through the non-vision grilles easily, but the design means nothing can be poked directly into the enclosure, thus increasing safety. These type of grilles are often seen in air conditioning applications.

We always allow a large safety margin between the live connections and the sides of the enclosure, which also means the enclosure is easy to work in during the assembly phase.

In some cases the hot air is collected from above and ducted away, to prevent the building itself being overheated.

Incoming ACB sections have their busbars arranged to complement the transformer enclosure.

Close coupling of the transformer to the switchboard means that the installation is compact and often simplifies the protection requirements. We are often required to provide CT links for class X CT's (Restricted Earth Fault) together with associated neutral to earth link within the main incomer section. Other protection and metering CT links are also provided as standard, to suit the requirements of each project.

External doors will often be fitted with access interlocks (eg Fortress, Castell) which prevent access until the HV circuit has been isolated.

We are familiar with many different transformer manufacturers products eg SGB, Zucchini, France Transfo, Ocrev etc.

This is a typical SGB transformer in the stores before being sent to site, with axial blowers (fans) at low level. Many transformers are sent direct to site due to their size, but some customers prefer to fully works assemble and test.